Minimize Work Content in Production and Maintenance and Reduce TOC Using Early-Stage Structural Design Optimization (2022-328-001)

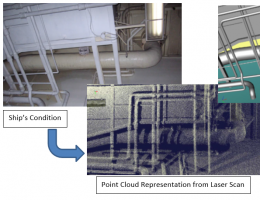

Mobile Laser Scan to CAD Analysis (2018-455-026)

LiftShip 2 (2018-451-003)

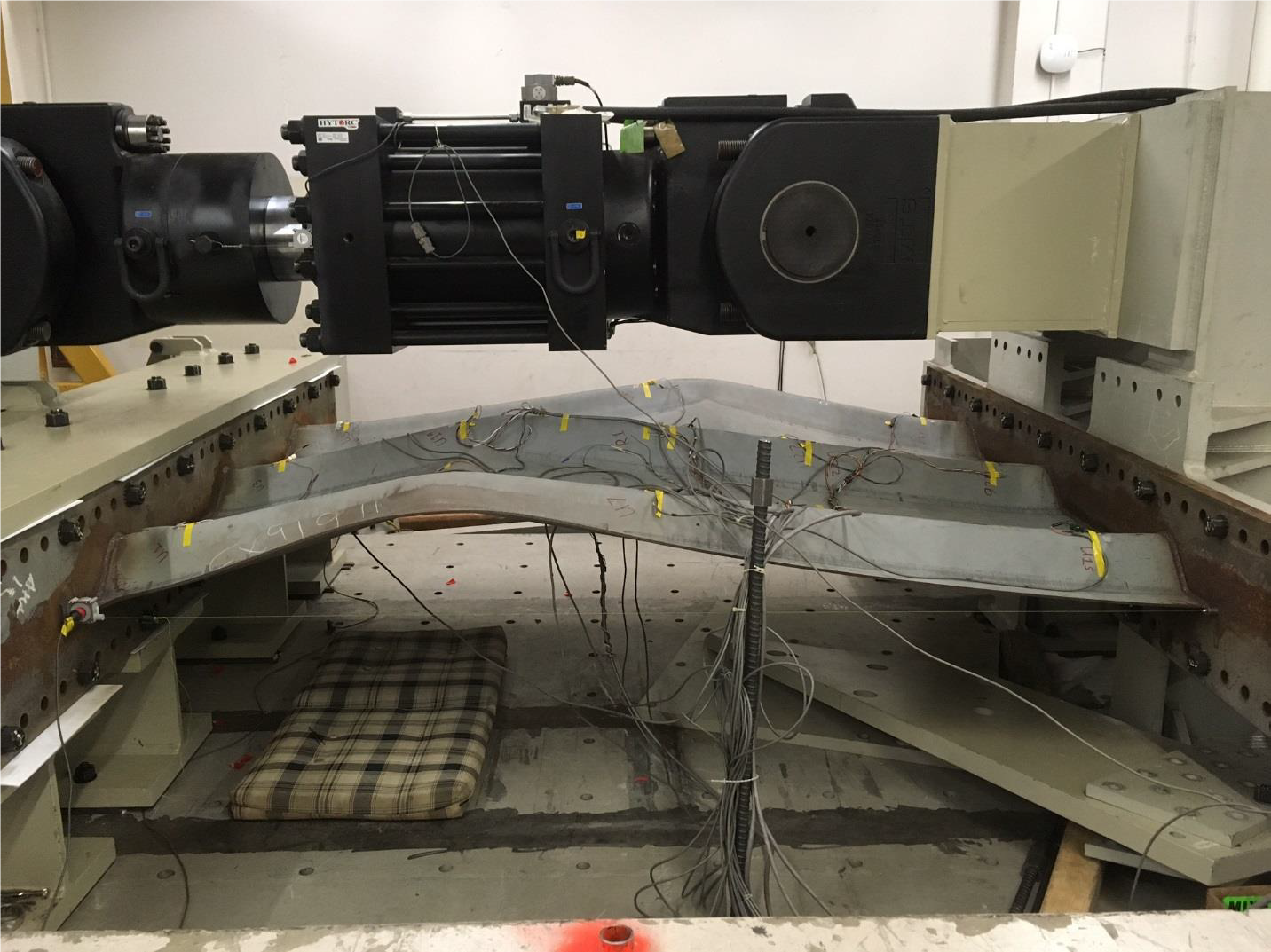

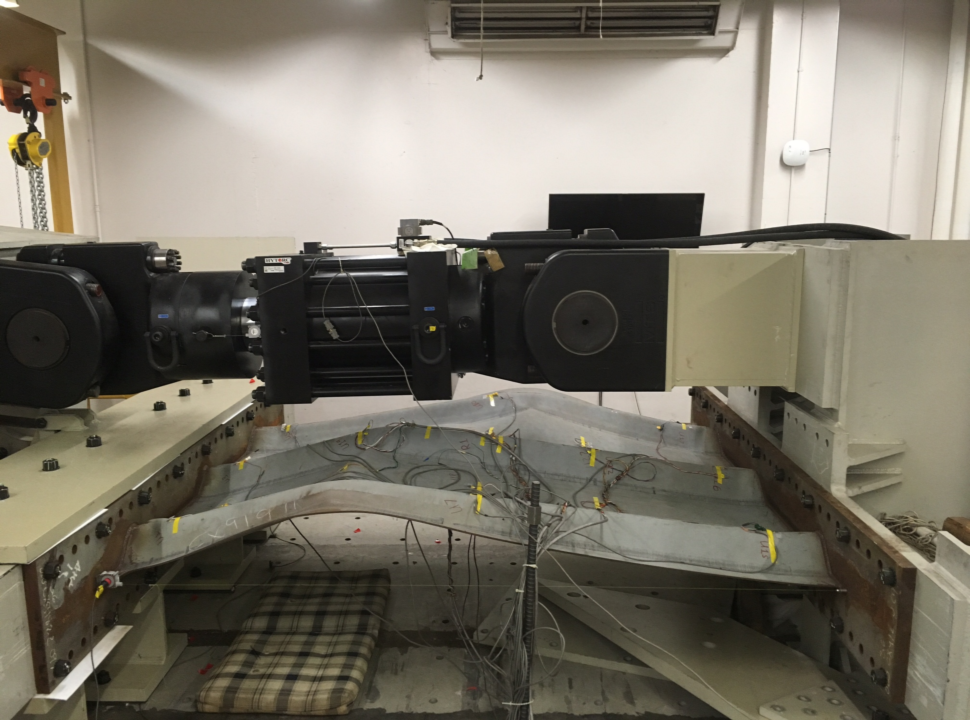

Fatigue Analysis of Swaged Bulkheads (2018-454-007)

Advanced Knowledge Provisioning Using Artificial Intelligence (AI) & Augmented Reality (AR) for Ship Repair

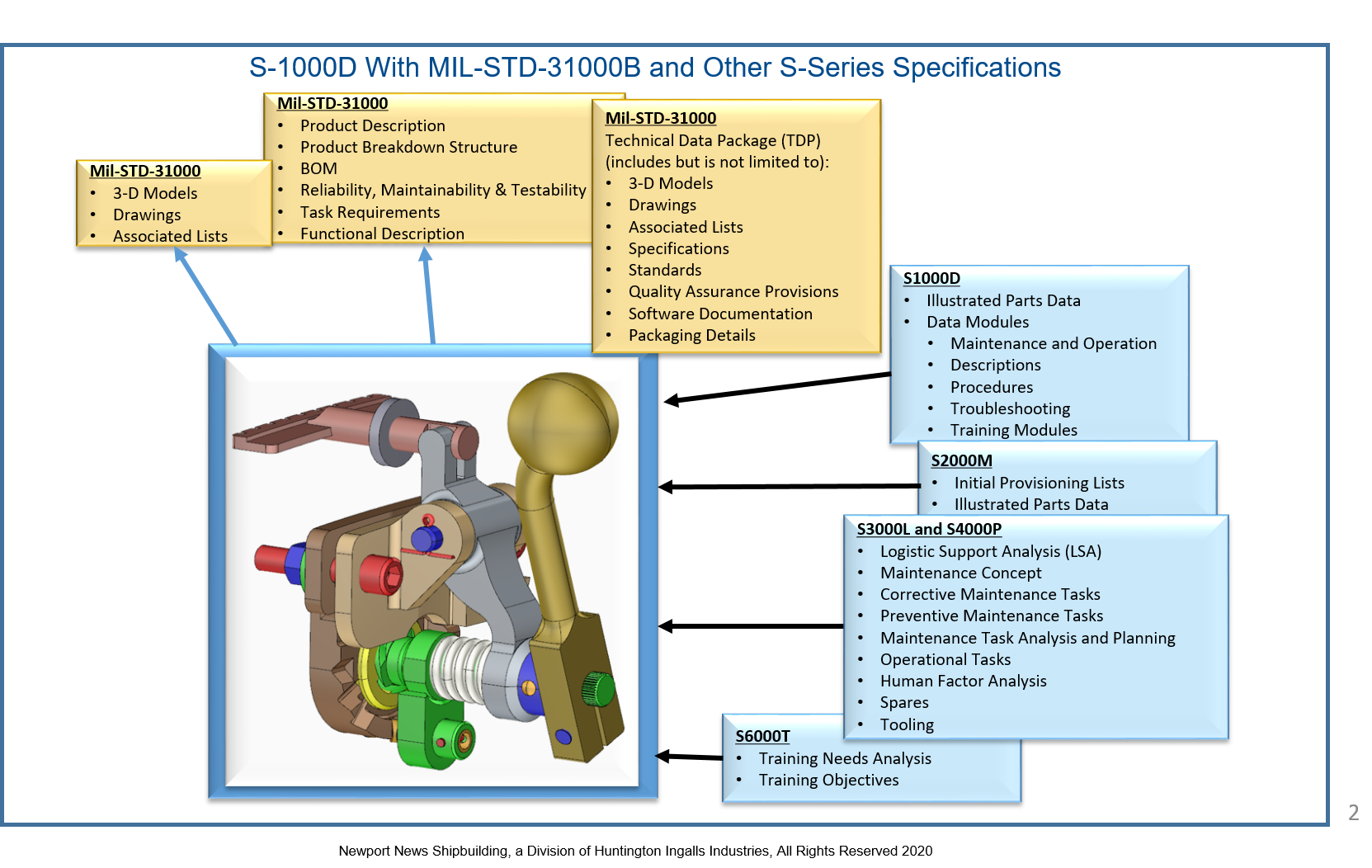

Minimum Standardized Content to Enable a Navy Digital Enterprise 2018-455-020

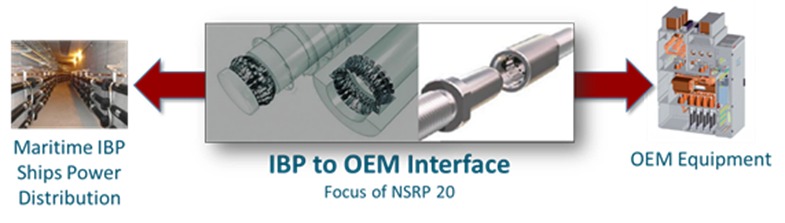

Research & Develop Insulated Bus Pipe (IBP) Standard Interface to Naval Electrical Equipment

Supply Chain Integrity-Blockchain for Smart Contracts

On-Board Ship 3-D Environment

Qualification Testing of Insulated Bus Pipe (IBP) for Shipboard Introduction

MINERVA: Mixed Reality System for Real-Time Construction Problem Resolution

Laser Scan to CAD Analysis

Cost Reduction of Shock Application

Tele-Welding- Remote Operation of Shipyard Welding (and other) Equipment

Integration of Scanning & Laser Peening Technology in Shipyards

Knowledge Provisioning to Improve First Time Quality of Ship Design

Land Based Case Study of Insulated Bus Pipe for Ship Design

LiftShip

SMART: Shipyard Mobile Applications in Real Time

Digital Deadweight Survey Project

Foundational Technology for Scanning & Laser Peening in Shipyards

Ship Structural Design Optimization for Improved Producibility and Enhanced Life-Cycle Performance

Standardization of Watertight Closures

3 Views to 3D

Common Interface Pilot Project-Phase 1

ARgos

Mitigation of Stress Corrosion Cracking, Cavitation Erosion & Forming Complex Shapes Using Laser Peening

Reduction of Total Ownership Cost (R-TOC) through Application of Design for Maintenance (DFM) Solutions

Swage Panel SVR Rule Development

Development and Applications of Standard Hull, Mechanical and Electrical Modules to Increase Flexibility in Ship Design Using DFA Principles

Flexible Infrastructure Qualification

Design for Maintenance Training

Improved Advanced Watertight Door Finalization Program

All-Platform Affordable LED Lighting

Open Architecture System Design for Modularity

Ship Cable Management

Design for Maintenance & Repair

Swaged Bulkhead Analysis Verification

Naval Vessel Ice Capability Optimization Effort

First Time Quality, NDE, and Fitness for Service Technology for Friction Stir Welding and Manufacturing Aluminum Panels for Ships

Common Parts Catalog Enhancements

Common Parts Catalog

Design for Producibility for Mid-Tier Shipyards

World Class Material Standards & Parametric Design Rules

Structural Fire Protection

spARky: Reducing Wiring Costs Using 3D Model and Augmented Reality

Digital Shipbuilding

Dynamic Change Awareness

In Service Ship Re-Documentation & Configuration Management

Ship Knowledge Management (SKM)

Sustainment Technologies for Ohio Replacement Class Submarine

Production Planning Integration with CAD

Product Model Driven Weld Management (PMDWM)